This hydraulic drilling attachment has higher productivity than a pneumatic drill being able to replace a dedicated hydraulic crawler drill. Diesel consumption is greatly reduced compared to a pneumatic set (trailer + compressor). The operator can operate the drill from outside the cabin, using the radio control, not exposing himself to risk situations. In a matter of minutes, with a single piece of equipment, three functions are achieved: drilling, demolition and excavation.

Advantages:

- Multiple drilling positions

- Low Investment Cost

- High Productivity

- Higher Reach

- Operational Confort

Hydraulic Drilling Attachment for Excavators for Quarries, Mines and Construction

Technical Data |

|---|

Fully hydraulic and needs a single operator

|

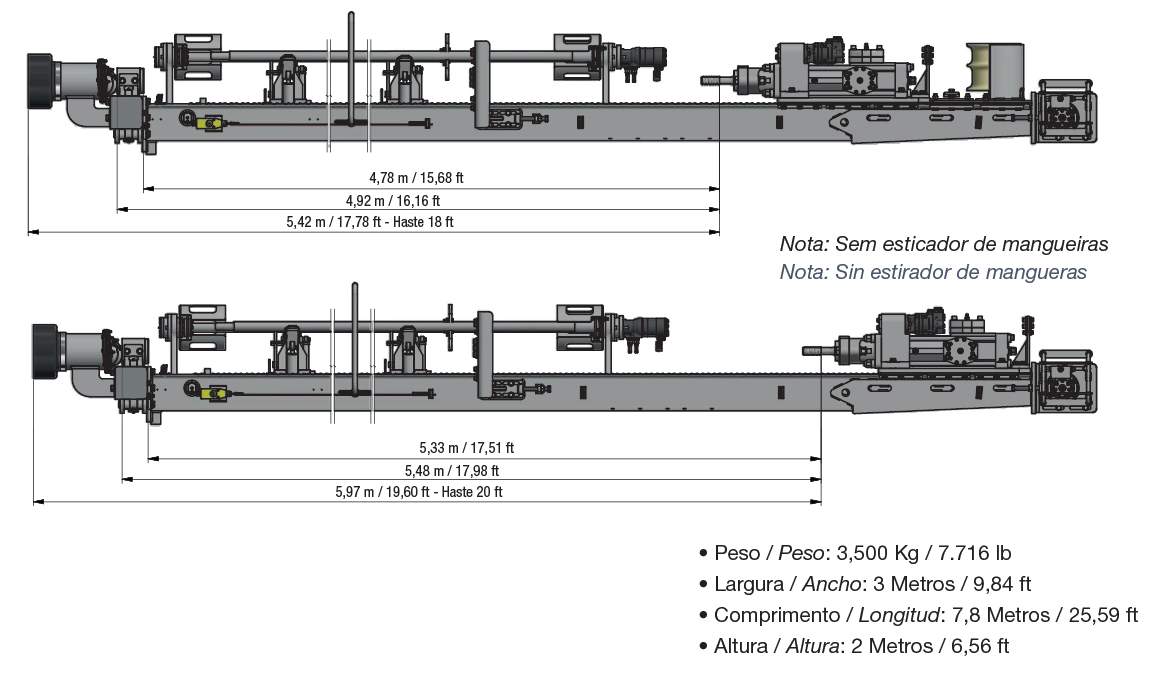

Hole Size: 2.1/2″ to 4″ (64 à 102 mm)

|

Digital panel inside the cabin with interactive display for monitoring and Depth Gauge (as an optional item)

|

Rod Changer, Rod Greaser, Hydraulic Centralizer and Hose Reel

|

Cleaning System with Water Injection or Dust Collector (as an optional item)

|

An air compressor 250cfm @100 psi is required along with the excavator for proper operation

|

Excavator Requirement : Plumbed with Auxiliary Kit 240-250 l/min @150 bar (64-66 GPM @2100 psi) and Air Compressor 250 CFM @ 100 psi (will depend on drilling diameter and depth)

|

AVAILABLE COMPONENTS | |

|---|---|

STANDARD | |

Secondary Rod Changer (1 rod) | |

Hydraulic Centralizer (Exclusive for SONIC 2000, just top hammer) | |

Anti-Jamming | |

OPTIONS | |

Protection (Hose and Valves) | Water Tank |

Emergency Button (installed on side of the mast) | |

Nitrogen Charger | Depth Gauge |

Protection (Feed Motor and Feed) | Dust Collector (Primary and Secondary) |

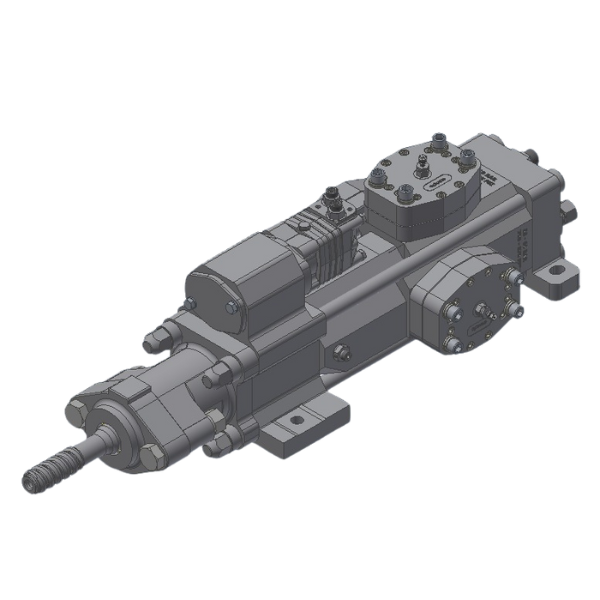

Surface Drifter W 19:

Technical Data | |

|---|---|

Working Pressure | 120-140 bar (2.030 PSI) |

Impact Power | 19 Kw (26 hp) |

Impact Frequency | 2.600 bpm |

Weight | 237 kg |

Rotation | 0 – 150 rpm |

Rotation Torque | 750 Nm (533 lbf/ft) |

Thread Type | T38 / T45 |

Hole Size | 2.1/2″ – 4″ |

Rod Length | 3,66m (12”) |